Underground Fiber Optic Cable Installation Standards

Placing cables underground has the added benefits of reducing transmission losses aiding planning consent and reduced risk of service supply loss through extreme weather.

Underground fiber optic cable installation standards. It defines a minimum level of quality for fiber optic cable installations. Pulling underground fiber optic cable. Standard guide for safety access rights construction liability and risk management for optical fiber networks in existing sewers. This practice covers the basic guidelines for installation of fiber optic cable in underground cable.

An incorrectly installed fiber cable can result in broken fibers and structural damage to the cable not a good outcome since service providers pay for and expect an uncompromised cable. The number of 90 degree turns on a pull shall not exceed 6 for aerial cables and 4 for underground cable in conduit. A new fiber optic installation standard. The two most common outdoor fiber optic cable installations in ohio are pole line aerial installation and underground cable installation.

Do not use this equipment to install fiber optic cable small rollers can make contact points that do not maintain the minimum bend radius of the cable. When installing optical cable what you don t know could really hurt you or damage your cable. 1 1 products and applications included this standard covers fiber optic cabling installed. When used cable ties should be hand tightened to be snug but loose enough to be moved along the cable by hand.

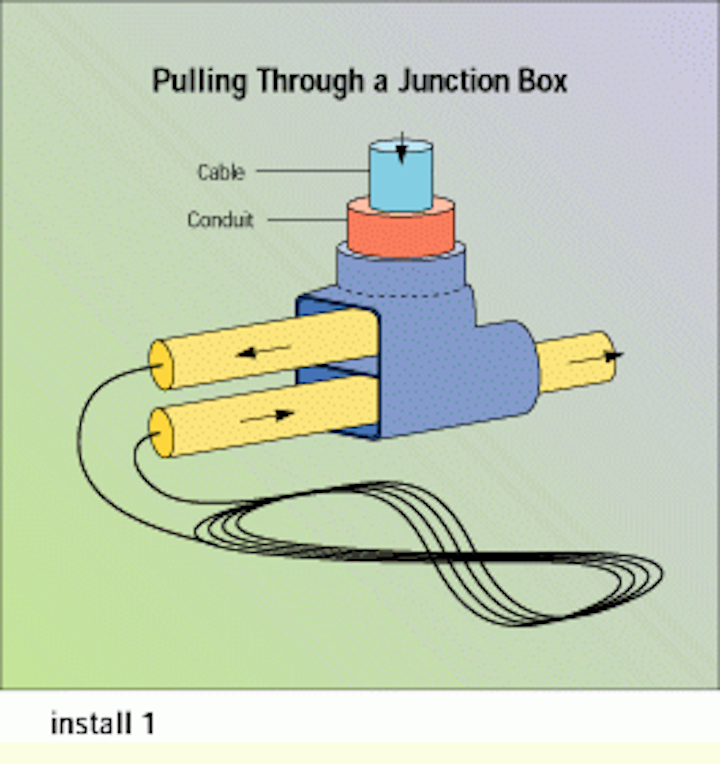

And testing cabling networks that use fiber optic cables and related components to carry signals for communications security control and similar purposes. In this blog we will talk about underground fiberoptic cable installation. And always use a swivel pulling eye because pulling tension will cause twisting forces on the cable. Number of 90 degree turns.

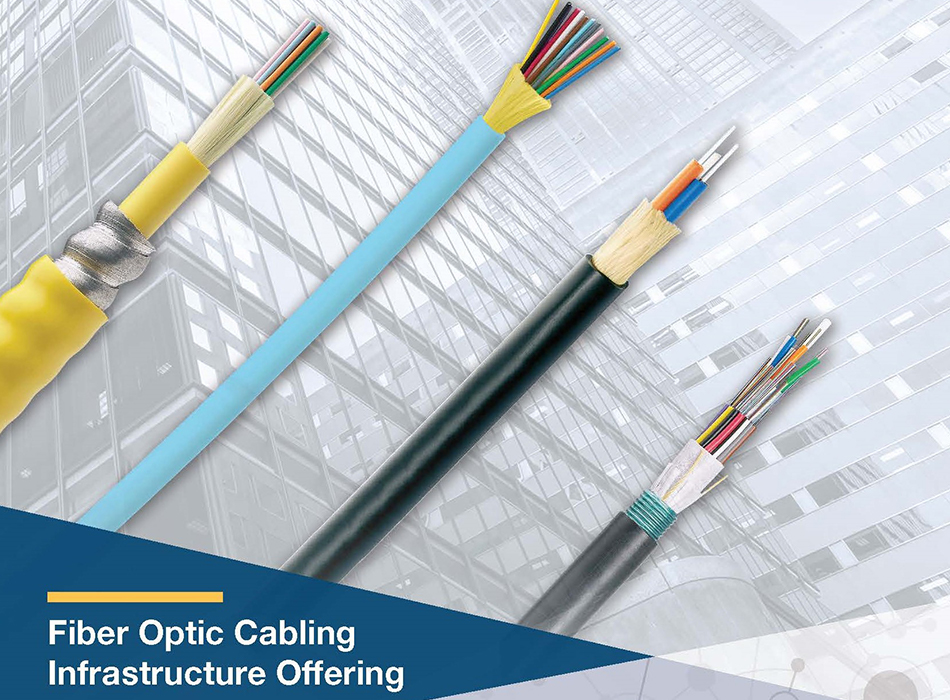

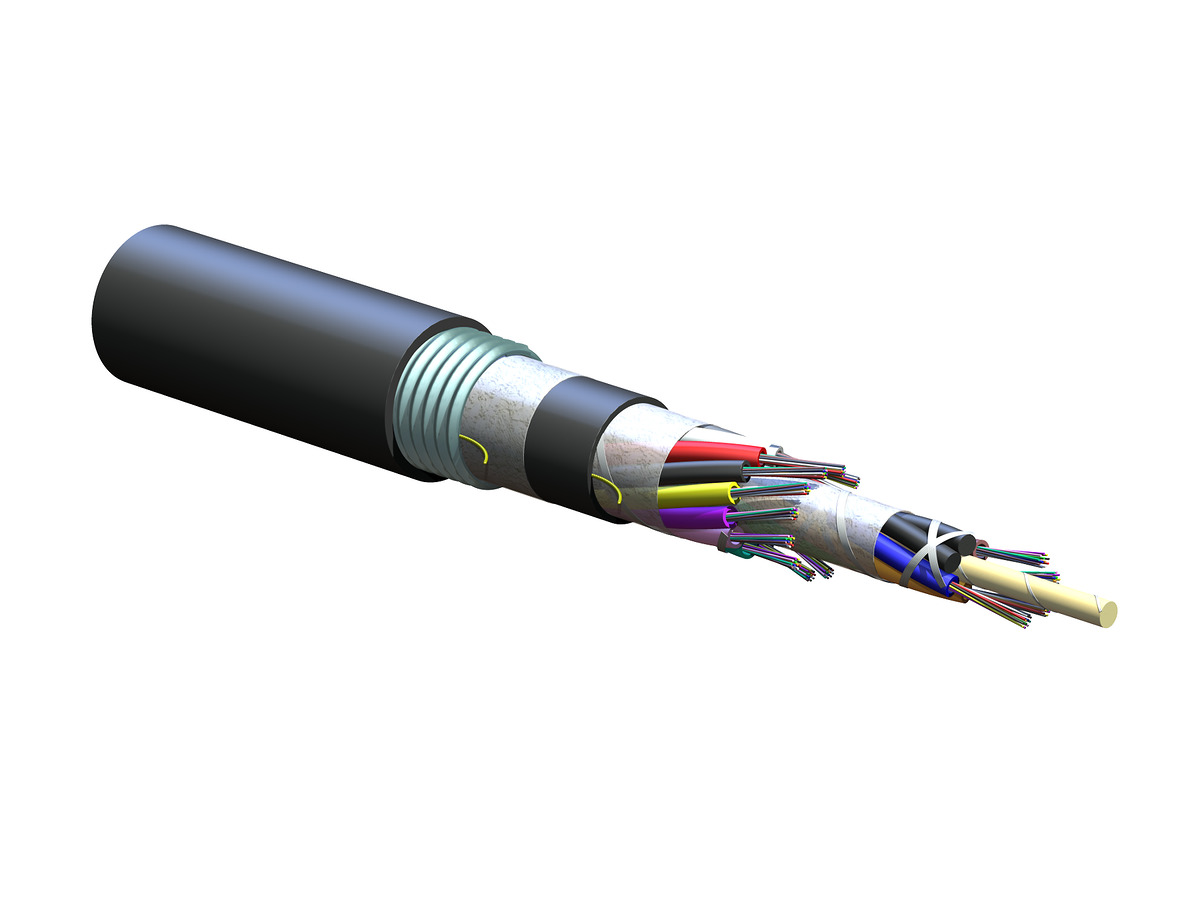

Cable ties used with many cables especially when tightened with an installation tool are harmful to fiber optic cables causing attenuation and potential fiber breakage. F2303 03 2015 standard practice for selection of gravity sewers suitable for installation of optical fiber cable and conduits. Installation guide for optical fibre cable edition 05 12 2002 rev 1 0 copyri g h t n e xans 2 002 all data subject to c h ange w i thout prior notice table of contents 1 safety warnings 2 working practice 3 precautions 4 storage 5 generality 1 pre installation procedure 6 fibre optic cable construction 1 fibre 2 buffer types. Keywords manholes winches sheaves jetting method.

Familiarizing yourselfwith standard 301 is a smart step to avoid such problems up until a little over a year ago an installation standard for optical cable didn t exist. In underground fiberoptic cable installation cables can be buried directly in a trench or placed into a buried duct.